Top-Performing Hydraulic Shock Design

- Hydraulic stop design outperforms market leader

- Seals and valves facilitate piston dampening in both up and down movements

- Smoothness of vibration absorption improves comfort and durability

- Consistent performance over the life of shock improves tire wear and lessens component wear

High-Performance Hydraulic Oil

High-viscosity oil offers remarkable performance in heavy-duty shock absorbers, ensuring consistent and reliable operation through a wide range of weather conditions and extreme heat generated in severe service applications. This type of oil maintains its consistency and protective qualities even in the harshest environments, which is crucial for shock absorbers that must endure significant stress and impact. Its ability to resist thermal breakdown means that it can effectively reduce wear and tear on the internal components of shock absorbers, prolonging their lifespan and enhancing their performance. Whether the shock absorbers are subjected to freezing temperatures or scorching heat, high-viscosity oil ensures that they continue to operate smoothly and efficiently, providing superior damping and stability. This makes high-viscosity oil an essential component for maintaining the durability and effectiveness of heavy-duty shock absorbers in demanding operational conditions.

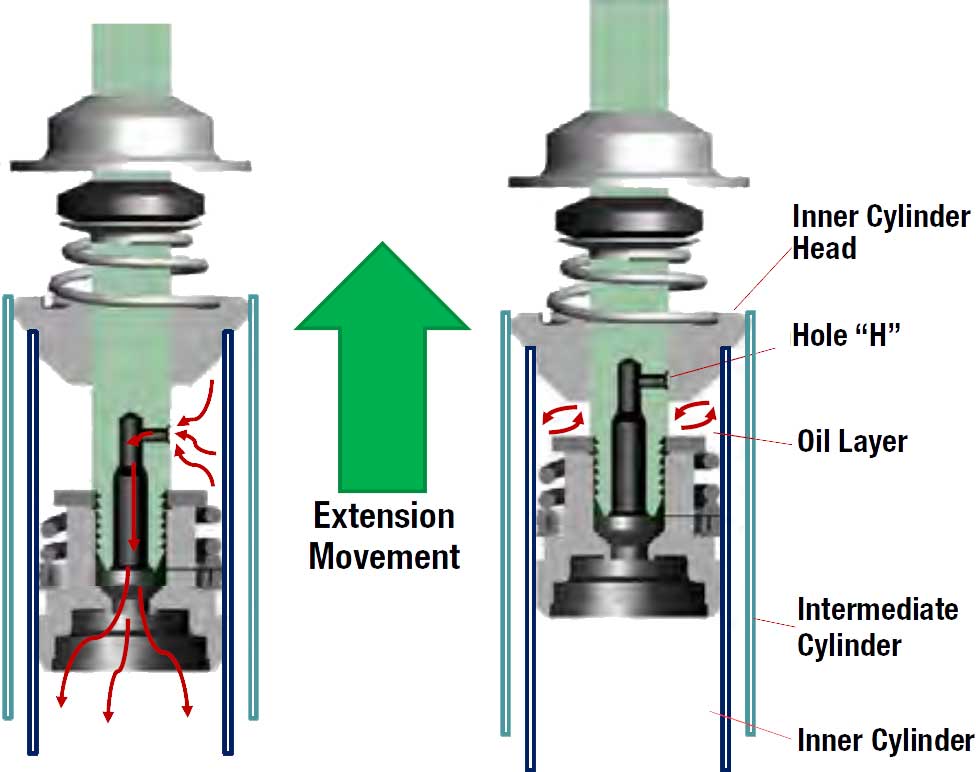

HYDRAULIC BUMPER DETAIL

The image below illustrates the inner workings of a hydraulic bumper within a shock absorber, particularly focusing on the extension movement phase. During this phase, the shock absorber extends, and the hydraulic stop design plays a crucial role in protecting the shock from topping out and causing damage to its components.

On the left side of the image, we see the initial state where the shock absorber is in the process of extending. As the inner cylinder moves upwards, it encounters resistance from the oil present within the system. This oil is depicted as flowing through specific pathways within the shock absorber.

On the right side of the image, the extension movement is shown to have progressed further. Here, the inner cylinder head has moved to cover the top hole, labeled as "Hole 'H'". When this hole is covered, it creates a barrier that traps a layer of oil between the inner cylinder head and the intermediate cylinder. This trapped oil layer acts as a cushion, absorbing the energy from the extension movement and preventing the shock absorber from extending too far or too quickly.

This cushioning effect is crucial for preventing the shock absorber from "topping out," which is when the piston reaches the end of its travel range and impacts the shock body. Such impacts can cause significant damage to the shock absorber's internal components, leading to reduced effectiveness and potential failure.

By utilizing high-viscosity oil, the shock absorber ensures that the oil layer remains consistent and effective in various temperature and pressure conditions. The oil's resistance to thermal breakdown and its stable viscosity under different environmental conditions ensure that the shock absorber can reliably provide damping and protection, even under severe service applications.

This hydraulic bumper mechanism, therefore, enhances the durability and performance of heavy-duty shock absorbers, ensuring they can withstand the rigors of demanding operational environments while maintaining smooth and stable operation.

Marathon Shocks

Designed & Built for the Long Haul

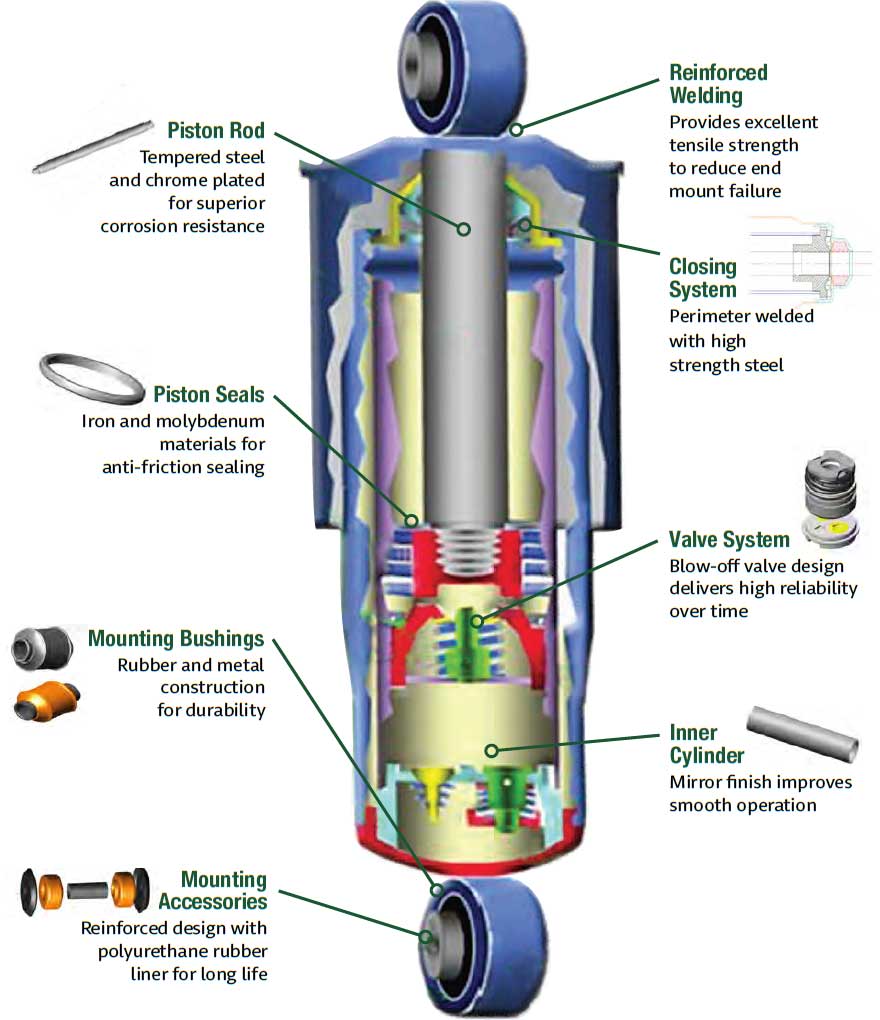

The cutaway image of the heavy-duty shock absorber reveals its sophisticated design, engineered to deliver optimal performance and durability in demanding conditions. Key components are labeled to highlight their functions and the advanced materials used to enhance the shock absorber's efficiency and lifespan.

- Piston Rod:

- Description:

The piston rod is made from tempered steel and is chrome-plated.

The piston rod is made from tempered steel and is chrome-plated. - Benefits: This construction provides superior corrosion resistance, ensuring the piston rod remains durable and performs reliably over time.

- Description:

- Piston Seals:

- Description: These seals are crafted from a combination of iron and molybdenum.

- Benefits: The materials used for the piston seals offer excellent anti-friction properties, ensuring a tight seal and reducing wear and tear, which enhances the overall efficiency of the shock absorber.

- Reinforced Welding:

- Description: The shock absorber features reinforced welding at critical points.

- Benefits: This welding provides excellent tensile strength, significantly reducing the risk of end mount failure under heavy loads and extreme conditions.

- Closing System:

- Description: The closing system involves perimeter welding using high-strength steel.

- Benefits: This method ensures a robust and secure closure, contributing to the overall durability and integrity of the shock absorber.

- Valve System:

- Description: The shock absorber utilizes a blow-off valve design.

- Benefits: This advanced valve system delivers high reliability over time, ensuring consistent damping performance and smooth operation even under varying loads and conditions.

- Mounting Bushings:

- Description: The mounting bushings are constructed from a combination of rubber and metal.

- Benefits: This combination provides durability and flexibility, allowing the bushings to absorb shocks and vibrations effectively, contributing to a smoother ride and protecting other components from excessive wear.

- Mounting Accessories:

- Description: These accessories feature a reinforced design with a polyurethane rubber liner.

- Benefits: The polyurethane liner ensures a long life for the mounting accessories, providing additional shock absorption and durability in various operating conditions.

- Inner Cylinder:

- Description: The inner cylinder has a mirror finish.

- Benefits: This smooth finish improves the operation of the shock absorber by reducing friction and wear, ensuring a consistent and reliable performance over time.

Find your Shock

Find the equivalent Marathon Shock Part number by either selecting the Manufacturer and then the part number or by entering the part number in the text box.